Kayan amfani da Jaka

Gilashin filastik

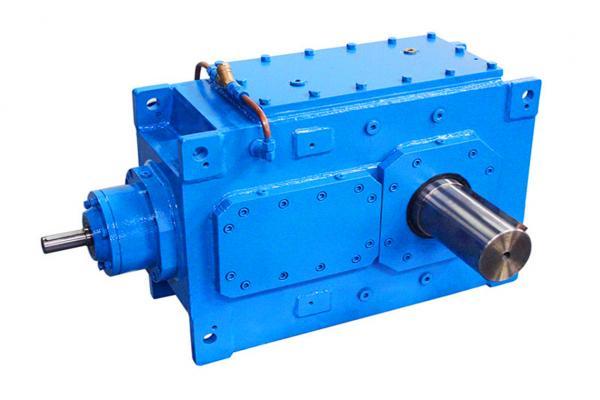

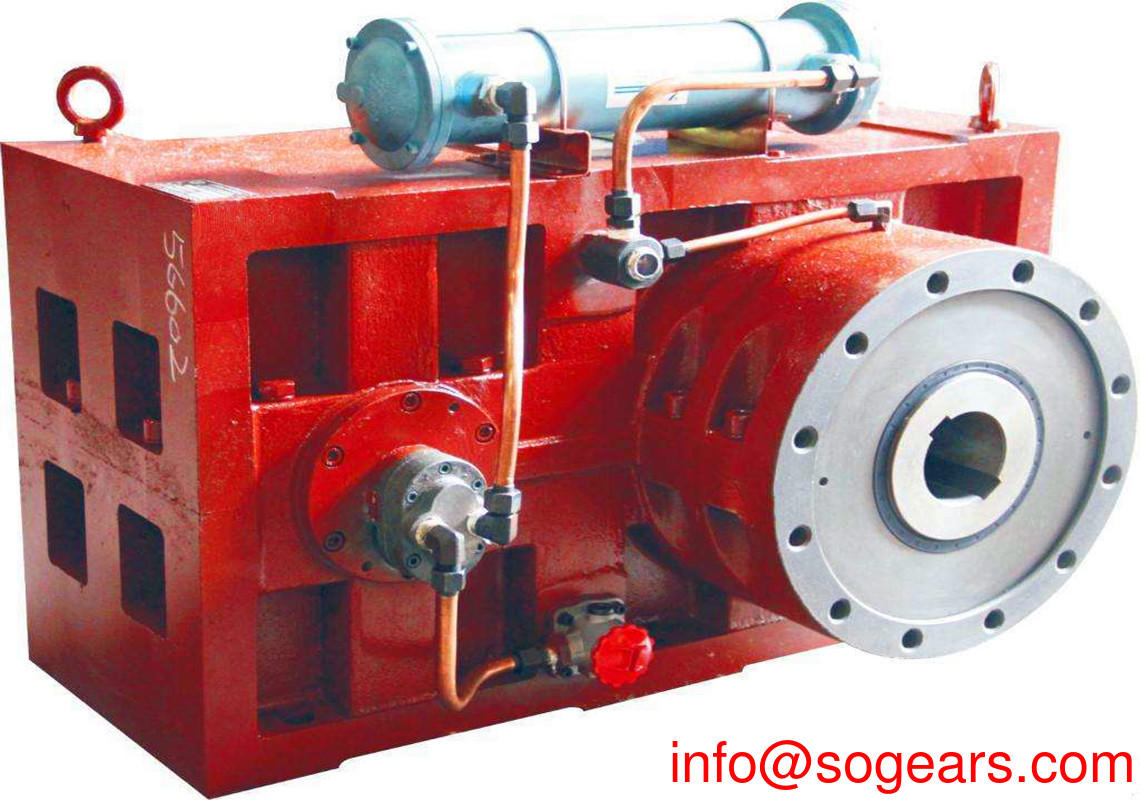

Filastik extruder Gearbox, masu kera akwatin gearbox, Akwatin gear na siyarwa, Gyaran Akwatin gear, Gishiri mai fitar da kaya, akwatin tagwayen dunƙule extruder gearbox

ZLYJ jerin wuya surface gearbox ne mai high-daidaici wuya-haƙori bel tura wurin zama watsa bangaren tsara don roba dunƙule extruder. Tsarin samfurin yana ɗaukar ƙayyadaddun ƙayyadaddun fasaha da aka ƙayyade a cikin JB/T8853-2001. Yana fasalta ƙarfe mai ƙarfi mai ƙarfi don kayan aiki da sassan shaft. Ana sarrafa kayan aikin ta hanyar carburizing, quenching da niƙa. Daidaiton Gear shine GB10095-88.6. Taurin saman haƙori HRC54-62. An shirya juzu'in juzu'i mai girma a ƙarshen gaban ramin fitarwa don jure ƙarfin axial ɗin aiki na dunƙule. Babban daidaitattun sassa kamar bearings da hatimin mai ana yin su ne da samfuran gida masu inganci, kuma ana iya sanye su da kayan da aka shigo da su bisa ga bukatun mai amfani. Duk injin yana da halaye na ƙananan ƙararrawa, ƙarfin ɗaukar nauyi, ingantaccen watsawa, ƙaramar amo da babban inganci. Ayyukan samfur ya kai matakin ci gaba na duniya.

Halayen Aiki:

Haɗuwa da akwatin da ƙwanƙwasa ƙwanƙwasa yana magance ƙarfin axial, kuma an shirya nauyin ma'auni a ɗakin mai na akwati don inganta amincin aiki.

Ana iya amfani da ƙananan gyare-gyare don daidaita nisa na tsakiya

Ƙarfin watsawa mai girma, zai iya jurewa babban karfin juyi da ƙarfin axial

Akwatin Gear na musamman don extruder shine kayan watsawa tare da babban nauyi mai ƙarfi saman haƙori tare da wurin turawa wanda aka ƙera tare da la'akari da samfuran kamanni na ƙasashen waje don ƙirar filastik. Tsarin samfurin yana ɗaukar ƙayyadaddun ƙayyadaddun fasaha waɗanda ZBJ19009-88 ya ƙulla. Halayensa shine cewa gears da sassan shaft an yi su ne da ƙarfe mai ƙarfi mai ƙarfi, ana sarrafa su ta hanyar carburizing, quenching da niƙa. Gear daidaito ne GB10095-88, matakin 6. Haƙori surface taurin HRC54 ~ 62. An shirya babban juzu'i mai girma a ƙarshen gaban ramin shigar da ramin don jure matsawar axial na dunƙule. Dukan injin yana da fa'idodin ƙaramin ƙararrawa, ƙarfin ɗaukar nauyi, ingantaccen watsawa, ƙaramin ƙara da inganci mai inganci.

Extruder na musamman Gearbox fasali:

--tsari na yau da kullun, kewayon watsawa mai fa'ida da kyau da rarraba ma'ana;

--Tsarin siffar ya dace da tsarin shigarwa na duniya duka-zagaye;

--Gear yana ƙasa ta hanyar ingantacciyar injin niƙa mai inganci tare da daidaitaccen watsawa, ƙaramar amo da ingancin 98% tsakanin matakai;

Injin Extrusion sadaukar da Gearbox masu dacewa yanayi:

1. Gudun madaidaicin maɗaukaki na Gearbox bai wuce 1500r / min ba.

2, yanayin yanayin aiki shine 0-35C. Lokacin da kewayon zafin jiki ya wuce tanadi, ana iya shirya na'urar dumama ko sanyaya daban gwargwadon buƙatun mai amfani.

- Gabatarwa

ZLYJ Plastic extruder Gearbox wani nau'i ne na madaidaicin ƙayyadaddun kayan aiki wanda aka tsara musamman don filastik mai dunƙulewa guda ɗaya / roba extruder. Saukewa: JB/T8853-2001 Cylindrical Plastic extruder Gearbox a matsayin tunani don ƙira, samfuran suna amfani da ƙaramin ƙarfe mai ƙarfi mai ƙarancin carbon don gears da gear shaft, tare da flank carbureted, quenched da ƙasa, don saduwa da madaidaicin gear a matakin 6 (GB/T 10095) da taurin hakora hakora HRC54 ~ 62. An ɗora ƙaton ƙwanƙwasa a gaban mashin fitarwa don ɗaukar bugun daga dunƙule.

- Yi Amfani da Gari

- Jujjuyawar shigarwar mai motsi zai zama ≤ 1500 rpm.

- Matsakaicin gudun abin tuƙi zai zama ≤ 20m/s.

- Yanayin zafin jiki na aiki zai kasance tsakanin -40 ℃ ~ 45 ℃. Preheat da man shafawa zuwa sama 0 ℃ ko zabi low zafin jiki lubricating mai lokacin da yanayi zafin jiki ne kasa 0 ℃.

lura:

- Juyawa yana samuwa duka gaba da baya. Koyaya, babban magudanar ruwa na wasu nau'ikan Filastik extruder Gearbox yana da famfon mai mai hanya guda ɗaya kamar yadda aka saba zuwa mashin fitarwa wanda ke juyawa agogo.

III. Nau'in Akwatin Gear Filastik

Samfurin sunaye: Lokacin da aka kawo, duk Akwatin Filastik Filastik ana haɗe su tare da farantin suna don tantance nau'in, iyawa, kwanan watan samarwa, lambar tsohuwar masana'anta da sauran fasalulluka don manufar kiyayewa, waɗanda ba za a cire su ba da gangan.

- Shigarwa da Haɗin Filastik Gearbox

- Tabbatar cewa tushen shigarwa na Plastics extruder Gearbox matakin ne, amintacce kuma barga. A hankali shimfida shigarwa a cikin yanayin aiki na musamman. Lokacin da duk ƙusoshin anga an ƙara su daidai gwargwado, tabbatar da cewa dunƙule da aka saka a cikin ramin fitarwa yana jujjuya kyauta kuma akai-akai.

- Kuskuren haɗin ramuwa zai yi nasara dangane da haɗin Filastik Extruder Gearbox zuwa babban mai motsi. Tabbatar da madaidaicin sashin haɗin kai na tsakiyar layin axial na Ramin shigarwar Gearbox Filastik extruder. Bincika karkacewar axial da ƙaurawar angular, karkacewar wanda biyun za su kasance cikin ƙimar da aka yarda na haɗakar da aka yi amfani da su.

- Bincika ƙarin ƙarfin radial na shaft na Filastik extruder Gearbox bisa ga samfurin samfurin bisa ga yanayin da dabaran bel, kayan aiki da dabaran sarkar ana amfani da su don shigarwa da fitar da ƙarfin tuƙi na Akwatin Filastik Extruder. A tsakiyar ɓangaren shigarwar shigarwa, ƙarin ƙarfin radial ba zai wuce (N), wanda lokacin shigar da Filastik extruder Gearbox (NM).

- Bayan shigarwa, cika cikin Akwatin Filastik ɗin Gearbox mai mai mai mai har sai an isa tsakiyar layin mai nuni lokacin rarrabawa daidai.

- Haɗa zuwa kuma kunna tsarin sanyaya ruwa don bincika ko haɗin gwiwa ya yi jini ko yayye.

- Kunna wuta don gudanar da Akwatin Gear Filastik na ɗan lokaci ba tare da lodi ba. Bincika ko bututun mai ya zubar da jini ko yayyo, sassan da sassan sun sassauta kuma kowace hayaniya ta faru. Ana iya mika akwatin Gear na Filastik idan komai yayi daidai.

hankali:

◇ Yanke da hana (ta alamar faɗakarwa, da sauransu) sake haɗa wutar lantarki zuwa injin kafin shigar da haɗin gwiwa.

◇ Ba a ba da izinin buga guduma ko wasu makamantan kayan aikin yayin hawa kayan haɗin gwiwa da ƙananan ginshiƙai zuwa ƙarshen shaft.

◇ Tabbatar da madaidaicin tashin hankali na bel lokacin shigar da dabaran bel.

◇ Kar a girka ko cire dunƙule da ƙarfi dangane da ɓangaren fitarwa.

◇ Dole ne a ba da murfin kariya ga ɓangarorin juyawa na waje na Akwatin Filastik ɗin Filastik (kamar haɗaɗɗen haɗaɗɗiya, bel ɗin bel, da sauransu).

◇ Cire tsaftar datti, datti ko wasu tabo a ƙarshen da gefen gefen shaft ɗin haɗin gwiwa. An ba da izini don tsaftacewa amma za a hana shi ya kwarara zuwa hatimin leɓe na abubuwan rufewa na ƙarshen shaft.

- Aiki na Plastic extruder Gearbox

Gwaje-gwaje kafin aiki:

- Kafin a fara aiki, duba ko Filastik ɗin Gearbox yana da mai mai zuwa matakin da ya dace a ciki. A kara mai idan aka yi karanci.

- Duk sassan haɗin kai za su kasance amintacce. Duk na'urorin kariya za su kasance cikakke.

- Bincika ko yanayin yanayi yana ƙasa da 0 ℃, idan eh, preheat mai mai zuwa sama da 0 ℃.

Aiki na Plastic extruder Gearbox:

- Guda Akwatin Gear Filastik na Filastik na mintuna 5 ~ 10 ba tare da kaya ba (idan Plastics extruder Gearbox yana sanye da famfon injin, fara famfo da farko) don sa mai daɗaɗɗen bearings da gears daidai. Idan an yi amfani da Gearbox na Filastik a karon farko, bayan aiki maras aiki, ƙara lodi mataki-mataki a kashi 20% na nauyin da aka ƙididdige kowane lokaci na awanni 1 ~ 2 har sai cikakken nauyin da aka ƙima. Saka cikin sabis idan komai yayi daidai.

- Yayin aikin, saka idanu kuma rubuta lokaci zuwa lokaci yanayin zafi na Akwatin Gear Extruder Plastics. Idan zafin zafin na'ura mai fitar da Filastik Gearbox ya wuce 70 ℃ ko kuma zafin mai ya wuce 100 ℃, dakatar da Akwatin Filastik don ganowa da magance matsalolin. Tuntuɓi sashen sabis na bayan-tallace-tallace idan ya cancanta. Sauya man mai mai mai kafin a sake fara Akwatin Gear na Filastik.

- Za a dakatar da Akwatin Gear Filastik kamar haka: Rufe hopper ɗin ciyarwa kuma, bayan duk kayan da ke cikin guga an fitar da su, kashe wutar lantarki zuwa Akwatin Filastik ɗin Filastik (idan Akwatin Filastik ɗin Gear yana sanye da kayan aikin. famfo na mota, rufe famfo da farko)

- Guda Akwatin Gear ɗin Filastik kowane mako 2 zuwa 3 a cikin taron na dogon zaman banza.

- Gudanar da matakan rigakafin tsatsa zuwa ciki da wajen Akwatin Filastik extruder a cikin yanayin zaman banza sama da watanni 6:

Cika man mai har zuwa cika, rufe ƙarshen sandar da saman da ba a fentin ba tare da kayan anti-tsatsa da kakin zuma da kuma kare tare da mai mai maiko hatimin leɓe na rufe sassan axles a kan shigar da tsatsa.

hankali:

◇ A lokacin farkon aiki, famfon mai na iya haifar da ƙara mai ƙarfi sakamakon yawan ɗanɗanon mai da kuma juriya mai yawa ga famfon mai, wanda sannu a hankali zai mutu tare da hauhawar zafin mai.

◇ Idan famfon mai ya haifar da ƙara mai ƙarfi yayin aiki na Plastic extruder Gearbox na yau da kullun, tsaftace tace mai don shigar da bututun mai.

◇ Saka idanu lokaci zuwa lokaci kwararar mai na Akwatin Filastik Extruder Gearbox yayin aiki, kuma, idan akwai, dakatar da Akwatin Fitar Filastik don magance matsalar.

- Gyara da Kulawa

- Tazarar lokaci na gyarawa da kulawa

|

Time tazara |

Gyara da gyara |

|

Aiki na yau da kullun |

Duba zafin Filastik mai bayyanawa Akwatin gear: ba fiye da 90 ℃ lokacin amfani da ma'adinai lubricating man fetur ba fiye da 100 ℃ lokacin amfani da roba lubricating man fetur Bincika ko akwai hayaniyar Filastik Gearbox extruder Bincika ko akwai yabo na Gearbox extruder Filastik |

|

Bayan 500 ~ 800 hours aiki |

Sauya mai na farko bayan aikin farko Bincika matakin mai don tantance cika mai |

|

Kowane aiki na awa 3000, aƙalla sau ɗaya rabin shekara |

Bincika man mai, kuma, idan akwai yanayi na waje ko datti, tabbatar da cewa abun cikin ruwa a cikin man mai kada ya wuce 500ppm Sauya man mai mai ma'adinai (awatar aiki ƙasa da 8h kowace rana) Tsaftace filogin iska |

|

Dangane da yanayin aiki, aƙalla sau ɗaya wata 3 |

Sauya man mai mai mai ma'adinai (aiki na ci gaba na dogon lokaci) Bincika ko akwai wani guntun haɗin gwiwa Bincika yanayin gurbatawa da na'urorin mai mai da sanyaya Tsaftace tace man mai kuma maye gurbin tacewa idan an buƙata |

|

Dangane da yanayin aiki, aƙalla sau ɗaya a shekara |

Sauya man shafawa na roba |

|

Kamar yadda yanayin muhalli da yanayin aiki yake |

Inganta ko maye gurbin fenti mai kariya (tsatsa) akan saman Tsaftace saman waje da na Akwatin Gear na Filastik Duba na'urorin haɗi sanye take |

- Tazarar lokaci na maye gurbin mai

A kai a kai maye gurbin mai mai na nau'in Plastics extruder Gearbox na musamman wanda ke aiki a cikin yanayi mai tsanani. Hoton da ke ƙasa yana nuna tazarar lokaci na maye gurbin mai a cikin yanayin al'ada. CLP HC yana nufin PAO roba mai mai.

(1) Lokacin aiki (2) Ci gaba da zafin jiki a cikin wanka mai mai (matsakaicin ƙimar 70 ℃)

VII. Binciken Laifi da Magani

|

laifinsu |

Sanadin |

Solutions |

|

laifinsu |

Sanadin |

Solutions |

|

Hayaniyar aiki marar al'ada da na yau da kullun |

A. Mirgina/hayaniyar niƙa: ɗaukar nauyi ya lalace B. Hayaniyar bugawa: tsere marar daidaituwa |

A. Bincika man mai da kuma maye gurbin abin da aka ɗaure B. Tuntuɓi Guomao |

Yayyo mai mai: Junction surface of Plastic extruder Gearbox Ƙarshen murfin murfin filastik Extruder Gearbox Murfin ramin gani na Plastics extruder Gearbox Wurin rufe bakin tuƙi Toshe fitar da mai Haɗin iska |

Sake haɗa sassan Kayan Filastik Gearbox Sake haɗa fastener Shigar da ba daidai ba na sassan rufewa Lalacewa/sharewar sassan rufewa Haɗin haɗin Yawan man mai na mai mai yawa Ba daidai ba shigarwa |

Bincika kusoshi masu haɗawa kuma ƙara matse su idan an buƙata Bincika ɓangaren hatimi kuma musanya shi idan an buƙata Duba matakin mai / inganta gajiya Tuntuɓi Guoma |

|

|

Hayaniyar aiki maras al'ada kuma ba na yau da kullun ba |

Rashin tsarkin mai |

Duba man mai, dakatar da aiki kuma tuntuɓi Guomao |

||||

|

Hayaniyar da ba ta al'ada ba a kafaffen sassa na Filastik extruder Gearbox |

Fastener na Filastik extruder Gearbox ya saki |

Bincika abubuwan haɗin gwiwa kuma yi amfani da waɗanda aka ƙayyade |

||||

|

Yawan zafin jiki na aiki |

A. Mai yawan mai B. Tsufa da lalacewar man mai C. Yawan kazanta a cikin mai D. Lalacewar famfo mai mai E. Laifin tsarin sanyaya |

A. Duba matakin mai kuma yi gyara idan an buƙata B. Duba lokacin maye gurbin man mai C. Duba mai mai mai D. Duba famfo mai mai kuma canza shi E. Duba tsarin sanyaya |

Maɗaukakin zafin jiki mai ƙarfi akan ɗaukar nauyi |

A. Rashin isasshen man mai B. Tsufa da lalacewar man mai C. Lalacewar famfo mai mai D. Lalacewar ɗauka |

A. Duba matakin mai kuma yi gyara idan an buƙata B. Duba lokacin maye gurbin man mai C. Duba famfo mai mai kuma canza shi D Bincika mai ɗaukar hoto kuma canza shi |

|

|

Zazzaɓi sama da ɗari akan wurin rufe magudanar ruwa a cikin lokacin aiki |

Rashin isasshen tsaftacewa na haɗin ƙarshen shaft yayin shigarwa Gudun-cikin sassan rufewa da ƙarshen shaft |

Tsaftace ƙarshen shaft Yi la'akari da shi a matsayin al'ada Tuntuɓi Guoma |

Lokacin tuntuɓar Guomao, da fatan za a ba da bayanan masu zuwa:

|

Cikakkun bayanai akan farantin suna |

- |

Nau'o'i da iyakokin laifuffuka |

- |

Lokaci da al'amuran kuskure sun faru |

- |

Sanadin |

VIII. Zabin Man shafawa

Za'a ƙayyade danko na mai mai lubricating daidai da yanayin saurin V, yanayin aiki ko hanyar sa mai na kayan aiki mai sauri:

Lokacin da V≤2.5m / s ko yanayi zafin jiki ne a cikin 35 ℃ ~ 50 ℃, zabi CKC320 matsakaici-load masana'antu rufaffiyar kaya mai ko CKD320 nauyi-load masana'antu rufaffiyar kaya mai;

Lokacin da aka yi amfani da lubrication na V-2.5m / s ko tilasta yin amfani da lubrication, zaɓi CKC220 matsakaici mai ɗaukar nauyi masana'antu rufaffiyar kayan mai ko CKD220 mai ɗaukar nauyi mai ɗaukar nauyi masana'antu rufaffiyar kaya.

Lubricant

Ba a ba da shawarar maiko mai mai don Filastik Gearbox extruder ba. Tuntube mu idan an buƙata.

Duba Annex-Teburin Kwatancen Mai Mai Lubricating ga kayayyakin mai na cikin gida da waje

- Saka sassan

Jerin Sassan Sawa na Akwatin Fitar Filastik

Jerin tattarawa na Akwatin Filastik Extruder

Annex - Teburin Kwatancen Mai Mai Lubricating (Oil Lubricating Mineral):

|

category |

ISOVG |

AGMA |

Maroki |

Nau'in Man Fetur |

Dankowa /40 ℃ |

Wurin Daskarewa ℃ |

|

category |

ISOVG |

AGMA |

Maroki |

Nau'in Man Fetur |

Dankowa /40 ℃ |

Wurin Daskarewa ℃ |

|

220 |

220 |

5EP |

Disamba |

Daga BG220 |

220 |

-21 |

320 |

320 |

6EP |

Disamba |

Daga BG320 |

320 |

-18 |

|

|

BP |

Energol GR-XP220 |

210 |

-27 |

BP |

Energol GR-XP320 |

305 |

-24 |

|||||||

|

Castrol |

Saukewa: SP220 |

220 |

-21 |

Castrol |

Saukewa: SP320 |

320 |

-21 |

|||||||

|

Castrol |

Alfamax 220 |

220 |

-24 |

Castrol |

Alfamax 320 |

320 |

-18 |

|||||||

|

Chevron |

Mai masana'antu EP220 |

220 |

-12 |

Chevron |

Mai masana'antu EP320 |

320 |

-9 |

|||||||

|

allahiya |

Farashin CLP220 |

220 |

-18 |

allahiya |

Farashin CLP320 |

320 |

-18 |

|||||||

|

Esso |

Spartan EP220 |

226 |

-30 |

Esso |

Spartan EP320 |

332 |

-27 |

|||||||

|

Exxon |

Spartan EP220 |

226 |

-30 |

Exxon |

Spartan EP320 |

332 |

-27 |

|||||||

|

Fuchs |

Renolin CLP220 Plus |

223 |

-23 |

Fuchs |

Renolin CLP320 Plus |

323 |

-21 |

|||||||

|

Gasa |

Gulf EP Lubricant HD220 |

219 |

-19 |

Gasa |

Gulf EP Lubricant HD320 |

300 |

-12 |

|||||||

|

Klüber |

Farashin GEM 1-220 |

220 |

-15 |

Klüber |

Farashin GEM 1-320 |

320 |

-15 |

|||||||

|

Kuwait |

Q8 Goya 220 |

220 |

-21 |

Kuwait |

Q8 Goya 320 |

320 |

-18 |

|||||||

|

mobile |

Mobilgear 630 |

207 |

-18 |

mobile |

Mobilgear 632 |

304 |

-18 |

|||||||

|

mobile |

Mobilgear XMP 220 |

220 |

-24 |

mobile |

Mobilgear XMP 320 |

320 |

-18 |

|||||||

|

Molub-Alloy |

MA-90/220 |

220 |

-18 |

Molub-Alloy |

MA-90/320 |

320 |

-15 |

|||||||

|

Optimol |

Farashin BM220 |

233 |

-15 |

Optimol |

Farashin BM320 |

338 |

-15 |

|||||||

|

Petro Kanada |

Ultima EP220 |

223 |

-30 |

Petro Kanada |

Ultima EP320 |

320 |

-21 |

|||||||

|

Shell |

Omala Oil F220 |

220 |

-21 |

Shell |

Omala Oil F320 |

320 |

-18 |

|||||||

|

Texaco |

Farashin 220 |

209 |

-21 |

Texaco |

Farashin 320 |

304 |

-18 |

|||||||

|

Jimlar |

Saukewa: EP220 |

220 |

-12 |

Jimlar |

Saukewa: EP320 |

320 |

-12 |

|||||||

|

Tribol |

Tashar 1100/220 |

222 |

-25 |

Tribol |

Tashar 1100/320 |

317 |

-23 |

|||||||

|

GB5903-95 |

Domestic |

Farashin CKC220 |

198 ~ 242 |

≤-8 |

GB5903-95 |

Domestic |

Farashin CKC320 |

288 ~ 352 |

≤-8 |

|||||

|

GB5903-95 |

Domestic |

Farashin CKD220 |

198 ~ 242 |

≤-8 |

GB5903-95 |

Domestic |

Farashin CKD320 |

288 ~ 352 |

≤-8 |

|||||

Annex - Teburin Kwatancen Mai Mai Lubricating (PaO Synthetic Lubricating Oil):

|

category |

ISOVG |

AGMA |

Maroki |

Nau'in Man Fetur |

Dangantakar cSt |

Wurin Daskarewa ℃ |

|

category |

ISOVG |

AGMA |

Maroki |

Nau'in Man Fetur |

Dangantakar cSt |

Wurin Daskarewa ℃ |

||

|

40 ℃ |

100 ℃ |

40 ℃ |

100 ℃ |

|||||||||||||

|

220 |

220 |

5EP |

allahiya |

Saukewa: HCLP220 |

220 |

25.1 |

-36 |

320 |

320 |

6EP |

allahiya |

Saukewa: HCLP320 |

320 |

33.9 |

-33 |

|

|

Esso |

Spartan Synthetic EP220 |

232 |

26.5 |

-39 |

Esso |

Spartan Synthetic EP320 |

328 |

34.3 |

-36 |

|||||||

|

Exxon |

Spartan Synthetic EP220 |

232 |

26.5 |

-39 |

Exxon |

Spartan Synthetic EP320 |

328 |

34.3 |

-36 |

|||||||

|

Fuchs |

Renolin Unisyn CLP220 |

221 |

25.8 |

-42 |

Fuchs |

Renolin Unisyn CLP320 |

315 |

33.3 |

-39 |

|||||||

|

Klüber |

Klübesynth EG 4-220 |

220 |

26 |

-40 |

Klüber |

Klübesynth EG 4-320 |

320 |

38 |

-40 |

|||||||

|

mobile |

Mobilgear SHC XMP 220 |

220 |

28.3 |

-45 |

mobile |

Mobilgear SHC XMP 320 |

320 |

37.4 |

-39 |

|||||||

|

mobile |

Mobilgear SHC 220 |

213 |

26 |

-51 |

mobile |

Mobilgear SHC 320 |

295 |

34 |

-48 |

|||||||

|

Optimol |

Optigear Synthic A220 |

210 |

23.5 |

-36 |

Optimol |

Optigear Synthic A320 |

290 |

30 |

-36 |

|||||||

|

Shell |

Omala Oil HD220 |

220 |

25.5 |

-48 |

Shell |

Omala Oil HD320 |

320 |

33.1 |

-42 |

|||||||

|

Texaco |

Saukewa: EP220 |

220 |

25.8 |

-48 |

Texaco |

Saukewa: EP320 |

320 |

35.2 |

-39 |

|||||||

|

Jimlar |

Carter EP/HT220 |

220 |

25 |

-39 |

Jimlar |

Carter EP/HT320 |

320 |

33 |

-36 |

|||||||

|

Tribol |

Tashar 1510/220 |

220 |

24.6 |

-42 |

Tribol |

Tashar 1510/320 |

330 |

33.2 |

-39 |

|||||||

|

Tribol |

Tashar 1710/220 |

220 |

- |

-33 |

Tribol |

Tashar 1710/320 |

320 |

- |

-30 |

|||||||

|

Domestic |

Babban Bango |

4405/220 |

221.3 |

- |

-42 |

|

|

|

|

|

|

|||||

|

Domestic |

Babban Bango |

4406/220 |

225.3 |

- |

-42 |

Domestic |

Babban Bango |

4406/320 |

330.5 |

- |

-40 |

|||||

Single dunƙule extruder manufa

An raba dunƙule guda ɗaya gabaɗaya zuwa sassa uku a cikin tsayin tasiri. An ƙayyade tsawon tasiri na sassan uku bisa ga diamita na dunƙule da kuma filin wasa na dunƙule. Gabaɗaya, an raba shi zuwa kashi ɗaya bisa uku.

Zaren ƙarshe na tashar kayan abu ana kiransa sashin isarwa: ana buƙatar kayan da za a yi filastik a nan, amma dole ne a riga an riga an haɗa shi kuma a haɗa shi. A da, tsohuwar ka'idar extrusion ta yi imanin cewa abu a nan ya kasance sako-sako, kuma daga baya ya tabbatar da cewa kayan a nan shi ne ainihin filogi mai ƙarfi, wato, kayan a nan yana da ƙarfi kamar toshe bayan an matse shi, don haka ya kasance. aikinsa matukar an kammala aikin isar da sako.

Sashe na biyu ana kiransa sashin matsawa. A wannan lokacin, ƙarar tsagi yana raguwa a hankali daga babba zuwa babba, kuma zafin jiki zai kai ga matakin filastik na kayan. Anan, matsawa yana samuwa ne ta hanyar isar da sashe na uku, inda aka matsa zuwa ɗaya, wanda ake kira matsa lamba na screw - 3: 1, wasu inji kuma sun canza, kuma kayan da aka gama filastik ya shiga mataki na uku.

Sashe na uku shi ne sashin ma'auni, inda kayan ke kiyaye zafin jiki na filastik, kamar yadda daidai da ƙima ke jigilar kayan narkewa kamar yadda famfon metering don samar da kai, a lokacin zafin jiki ba zai iya zama ƙasa da zafin jiki na filastik ba, gabaɗaya dan kadan mafi girma. .

Editan ceton makamashi Extruder

Ana iya raba makamashin makamashi na extruder zuwa sassa biyu: ɗaya shine ɓangaren wutar lantarki kuma ɗayan shine ɓangaren dumama.

Ajiye wuta: Yawancin inverters ana amfani da su. Hanyar ceton makamashi shine don adana ragowar makamashin motar. Misali, ainihin ikon motar shine 50Hz, kuma kuna buƙatar 30Hz kawai a samarwa don samar da isasshen. Yawan amfani da makamashin banza ne. Washe, mai inverter shine ya canza ƙarfin wutar lantarki na motar don cimma nasarar ceton makamashi.

Ajiye makamashi a cikin ɓangaren dumama: Mafi yawan tanadin makamashi a cikin dumama shine ceton kuzari ta hanyar hita lantarki, kuma ƙimar ceton makamashi kusan kashi 30% ~ 70% na tsohuwar zoben resistor.

aiki

Kayan filastik yana shiga cikin extruder daga hopper, kuma ana jigilar shi gaba ta hanyar juyawa na dunƙule. A lokacin motsi na gaba, kayan yana zafi da ganga, an lalata shi ta dunƙule kuma an matsa don narke kayan. Don haka, ana samun canji tsakanin jihohi uku na yanayin gilashin, babban matsayi na roba, da yanayin kwararar danko.

A cikin yanayin matsi, kayan da ke cikin yanayin kwararar danko yana wucewa ta hanyar mutu yana da wani nau'i, sa'an nan kuma ya zama ci gaba da ke da ɓangaren giciye da kuma siffar baki bisa ga mutuwar. Sa'an nan kuma a sanyaya shi a siffata shi don zama yanayin gilashi, ta yadda za a sami sashin da za a sarrafa.

Editan abun ciki

A cikin extruder, gabaɗaya, mafi mahimmanci kuma mafi mahimmanci shine mai fitar da dunƙule guda ɗaya. Ya ƙunshi: sassa shida: watsawa, na'urar ciyarwa, ganga, dunƙule, injin injin da mutu.

Sashen watsa

Bangaren watsawa yawanci ya ƙunshi injin lantarki, akwatin ragi da bearings. A lokacin aiwatar da extrusion, gudun dunƙule dole ne ya tsaya tsayin daka kuma ba zai iya canzawa tare da canjin ɗigon ɗigon ba, ta yadda za a kula da ingancin samfurin da aka samu. Koyaya, a lokuta daban-daban, ana iya buƙatar jujjuyawar don cimma buƙatun cewa na'ura ɗaya na iya fitar da robobi daban-daban ko samfuran daban-daban. Sabili da haka, wannan ɓangaren gabaɗaya yana amfani da motar motsa jiki ta AC, injin DC da sauran na'urori don cimma canjin saurin stepless, babban saurin dunƙule shine 10 ~ 100 rev / min.

Ayyukan tsarin watsawa shine fitar da kullun, wanda ke ba da karfin juzu'i da saurin da ake bukata a lokacin aikin extrusion, yawanci yana kunshe da motar motsa jiki, Gearbox da bearing. A ƙarƙashin yanayin cewa tsarin shine ainihin iri ɗaya, farashin masana'anta na Gearbox ya yi daidai da girmansa da nauyinsa na waje. Saboda siffar da nauyin Gearbox suna da girma, yana nufin cewa akwai abubuwa da yawa da ake cinyewa a lokacin masana'antu, kuma nau'ikan da aka yi amfani da su ma suna da girma, wanda ke ƙara yawan farashin masana'anta.

Na'urar ciyarwa

Yawancin kayan abinci ana pelletized, amma kuma ana iya amfani da tsiri ko foda. Kayan aikin caji yawanci yana amfani da hopper conical tare da ƙarar ƙarar da ake buƙata na akalla sa'a ɗaya. Ana ba da na'urar kashewa a ƙasan hopper don daidaitawa da yanke kwararar ruwa, kuma an sanya rami mai gani da na'urar auna a gefen hopper. Wasu hoppers kuma na iya samun na'urar rage matsi ko na'urar dumama wanda ke hana kayan abinci sha daga iskar, ko kuma wasu daga cikin harsashi na iya samun nasu mai tayar da hankali don ciyarwa ta atomatik ko ciyarwa.

Hoto

Gabaɗaya ana yin hopper a cikin siffa mai ma'ana. Ana buɗe taga a gefen hopper don lura da matakin kayan da yanayin ciyarwa. Kasan hopper yana da ƙofar buɗewa da rufewa don tsayawa da daidaita adadin ciyarwa. Rufe saman hopper don hana ƙura, danshi da ƙazanta daga fadawa cikinsa. Lokacin zabar kayan hopper, yana da kyau a yi amfani da nauyi, juriya da lalata da kayan injin mai sauƙi, gabaɗaya ta amfani da aluminum da faranti na bakin karfe. Girman hopper ya dogara da girman mai fitar da kayan aiki da kuma hanyar lodawa. Kullum, adadin extrusion na extruder yana daga 1 zuwa 1.5 hours.

Akwai nau'ikan hanyoyin ciyarwa iri biyu: ciyar da hannu da ciyarwa ta atomatik. Ciyarwar ta atomatik ya haɗa da ciyarwar bazara, ciyarwar fashewa, ciyarwar injin, isar da bel da makamantansu. Gabaɗaya, ana ɗora ƙananan ƙwanƙwasa da hannu kuma ana loda manyan masu fitar da su ta atomatik.

Rarraba hanyoyin ciyarwa

1 Ciyarwar nauyi:

Ƙa'ida - Kayan yana shiga ganga ta nauyinsa, ciki har da ciyar da hannu, ciyarwar bazara, da fashewa.

Siffofin - tsari mai sauƙi da ƙananan farashi. Duk da haka, yana da sauƙi don haifar da abinci marar daidaituwa, wanda ke shafar ingancin sassan. Ya dace ne kawai don ƙananan ƙananan extruders.

2 Ciyarwar dole:

Ƙa'ida - Sanya na'ura a cikin hopper wanda ke amfani da matsa lamba na waje zuwa kayan, tilasta kayan cikin ganga na extruder.

Siffofin - na iya shawo kan lamarin "gada", don haka ciyarwar ta kasance ko da. The feed dunƙule ne kora da extruder dunƙule ta hanyar drive sarkar don daidaita da gudu zuwa dunƙule gudun. Za'a iya kunna na'urar kariya ta wuce gona da iri lokacin da aka toshe tashar ciyarwa, don haka guje wa lalacewa ga na'urar ciyarwa.

harsashi

Gabaɗaya, ganga kayan ƙarfe ne da aka yi da ƙarfe mai ƙarfe ko kuma bututun ƙarfe da aka yi da ƙarfe na ƙarfe. Halayensa na asali shine babban zafin jiki da juriya na matsa lamba, ƙarfi mai ƙarfi da juriya na lalata. Gabaɗaya, tsayin ganga ya ninka diamita sau 15 zuwa 30, kuma tsayin ya kai cewa kayan sun yi zafi sosai kuma an yi musu filastik iri ɗaya. Ganga ya kamata ya kasance yana da isasshen kauri da kauri. Ya kamata ciki ya zama santsi, amma wasu ganga an zana su da tsagi daban-daban don ƙara juzu'i tare da filastik. Ana samar da masu wutar lantarki, na'urorin sarrafa zafin jiki da tsarin sanyaya a waje da ganga tare da masu tsayayya, inductor da sauran hanyoyin dumama.

Akwai nau'ikan abu guda uku a cikin ganga:

(1) ganga mai mahimmanci

Hanyar sarrafawa - sarrafawa akan dukkan kayan.

Abũbuwan amfãni - mai sauƙi don tabbatar da daidaiton masana'anta da daidaiton haɗuwa, na iya sauƙaƙe aikin haɗin gwiwa, silinda yana mai tsanani a ko'ina, da ƙarin aikace-aikace.

Rashin hasara - Saboda girman girman ganga da manyan buƙatun sarrafawa, abubuwan da ake buƙata don sarrafa kayan aiki ma suna da tsauri. Tsarin ciki na ganga yana da wuyar gyarawa bayan lalacewa.

(2) Kayan haɗin gwiwa

Hanyar sarrafawa - ana sarrafa ganga a matakai da yawa, sa'an nan kuma an haɗa sassan ta hanyar flanges ko wasu nau'i.

Abũbuwan amfãni - aiki mai sauƙi, mai sauƙi don canza yanayin yanayin, yawanci ana amfani dashi don canza yanayin rabo na dunƙule.

Disadvantages - high aiki madaidaicin bukatun, saboda da yawa segments, da wuya a tabbatar da coaxiality na kowane kashi, da flange dangane karya da uniformity na ganga dumama, ƙara zafi hasãra, dumama da sanyaya tsarin saituna da kiyayewa More wuya.

(3) ganga bimetallic

Hanyar sarrafawa - Cika ko jefa wani Layer na kayan ƙarfe na gami a cikin gindin karfen carbon na yau da kullun ko simintin ƙarfe. Ba wai kawai ya dace da buƙatun kayan ganga ba, amma har ma yana adana kayan ƙarfe masu daraja.

1 Bushing cartridge: An saka harsashi tare da bushing gami da maye gurbi. Ajiye karafa masu daraja, ana iya maye gurbin bushings, kuma an ƙara rayuwar ganga. Amma ƙirarsa, masana'anta da haɗuwa sun fi rikitarwa.

2 Simintin Ganga: Ana jefa ƙwarya mai ƙauri mai kauri kusan mm 2 akan bangon ciki na ganga, sannan ana samun diamita na ciki da ake buƙata ta hanyar niƙa. Gilashin alloy yana da alaƙa da tushe na ganga, kuma haɗin kai tare da tsayin axial na ganga yana da daidaituwa, ba shi da hali don kwasfa, ba ya fashe, yana da kyakkyawan aikin zamiya, kuma yana da juriya mai girma. tsawon rai.

1) An buɗe tsagi mai tsayi na bangon ciki na sashin ciyar da ganga

Don haɓaka ƙimar jigilar daskararrun, hanya ɗaya ita ce ƙara ƙimar juzu'i na saman silinda ta ingantaccen ka'idar sufuri. Wata hanya ita ce ƙara yanki na kayan a tashar tashar abinci ta hanyar giciye a tsaye zuwa ga madaidaicin dunƙule. Samar da tsagi mai tsayi a bangon ciki na sashin ciyar da ganga da taper na bangon ciki na sashin sashin ciyarwa kusa da tashar ciyarwa shine takamaiman hanyoyin guda biyu.

2) Ganga sashin ciyarwar tilasta sanyaya

Har ila yau, akwai hanyar da za a ƙara yawan daskararrun da aka yi jigilar su. Shi ne don kwantar da ganga sashen ciyarwa, manufar ita ce kiyaye zafin jiki na kayan da za a isar da shi a ƙasa da wuri mai laushi ko narkewa, don kauce wa bayyanar fim din narke don kula da ƙaƙƙarfan ƙaƙƙarfan kayan abu.

Tare da hanyar da ke sama, ana ƙara yawan isarwa daga 0.3 zuwa 0.6, kuma adadin extrusion ba shi da mahimmanci ga canje-canje a matsa lamba na kai.

Screw shine zuciyar mai fitar da wuta kuma shine mahimmin sashi na extruder. Ayyukan dunƙule yana ƙayyade yawan aiki, ingancin filastik, tarwatsawar filler, narke zafin jiki, amfani da wutar lantarki, da dai sauransu na extruder. . Yana da mafi mahimmancin sashi na extruder, wanda zai iya tasiri kai tsaye ga kewayon aikace-aikacen da kuma samar da ingantaccen kayan aiki. Juyawa na dunƙule yana haifar da matsananciyar matsa lamba akan filastik. Filastik na iya motsawa, matsawa da samun ɗan zafi daga gogayya a cikin silinda. Ana haɗe robobin da filastik a lokacin motsi na Silinda, kuma yanayin kwararar ɗanɗano Narke yana siffata yayin da ake fitar da shi don gudana ta cikin mutu don samun siffar da ake so. Kamar ganga, dunƙule kuma an yi shi da wani babban ƙarfi, zafi da juriya ga lalata.

Saboda nau'in robobi, kayansu ma sun bambanta. Sabili da haka, a cikin ainihin aiki, don dacewa da buƙatun sarrafa filastik daban-daban, nau'ikan screws da ake buƙata sun bambanta, kuma tsarin kuma sun bambanta. Don haɓaka ingancin robobi don haɓaka sufuri, extrusion, haɗuwa da filastik.

Hoton yana nuna wasu skru gama gari. Siffofin asali waɗanda ke nuna halayen dunƙule sun haɗa da masu zuwa: diamita, rabon al'amari, rabon matsawa, farar, zurfin tsagi, kusurwar helix, dunƙulewa da share ganga, da makamantansu. Mafi yawan diamita na dunƙule D shine kusan 45 zuwa 150 mm. Yayin da diamita na dunƙule ya karu, ƙarfin aiki na extruder yana ƙaruwa daidai, kuma yawan aiki na extruder yana daidai da murabba'in diamita na dunƙule D. Matsakaicin tsayin inganci zuwa diamita na sashin aiki na dunƙule (wanda ake nufi da shi). zuwa matsayin yanayin rabo, wanda aka bayyana azaman L/D) yawanci shine 18 ~ 25. Babban L / D na iya inganta rarraba zafin jiki na kayan abu, sauƙaƙe haɗuwa da filastik na filastik, da rage raguwa da komawa baya.

Inganta ƙarfin samarwa na extruder, L / D babban dunƙule yana da ƙarfin daidaitawa kuma ana iya amfani dashi don extrusion na robobi daban-daban; duk da haka, lokacin da L / D ya yi girma sosai, robobi za su lalace ta lokacin dumama da dunƙule Lokacin da nauyin kai ya ƙaru, ƙarshen kyauta yana jujjuyawa da sag, wanda ke haifar da sauƙin abu tsakanin dunƙule da dunƙule. dunƙule, kuma yana sa tsarin masana'anta da wahala; an ƙara yawan amfani da wutar lantarki na extruder. Ƙunƙarar da ta yi tsayi da yawa na iya haifar da ƙarancin filastik na durƙusa.

Rabin bambanci tsakanin diamita na ciki na ganga da diamita na dunƙule ana kiransa rata δ, wanda zai iya rinjayar yawan aiki na extruder. Yayin da δ ke ƙaruwa, yawan aiki yana raguwa. Yawancin lokaci, iko δ ya fi dacewa game da 0.1 zuwa 0.6 mm. δ yana da ƙananan, kayan aiki yana ƙarƙashin babban tasiri mai mahimmanci, wanda ke da amfani ga plasticization, amma δ yana da ƙananan ƙananan, aiki mai karfi mai karfi yana haifar da lalacewar injiniya na thermal na kayan, kuma a lokaci guda, dunƙule yana da sauƙin rataye ko shafa a bangon silinda, kuma Lokacin da δ ya yi ƙanƙara, kusan babu yoyo ko koma baya na kayan, wanda ke shafar haɗakar narkewar zuwa ɗanɗano.

kusurwar helix Φ ita ce kusurwa tsakanin zaren da ɓangaren giciye na dunƙule. Yayin da Φ ya karu, yawan yawan aiki na extruder yana ƙaruwa, amma tasirin raguwa da ƙarfin matsi akan filastik an rage. Yawancin lokaci, kusurwar helix yana tsakanin 10 ° da 30 digiri. Tsakanin °, tare da jagorancin canji na tsawon tsayin daka, sau da yawa ta yin amfani da madaidaicin ma'auni, ɗaukar farar daidai da diamita, ƙimar Φ kusan 17 ° 41 '

Mafi girman rabon matsawa, mafi girman rabon matsawa wanda filastik ke karɓa. Lokacin da tsagi ba shi da zurfi, zai iya haifar da ƙananan ƙima don filastik, wanda ke da amfani ga canjin zafi tsakanin bangon ganga da kayan aiki. Mafi girman haɗakar kayan abu da ingancin filastik, ƙananan yawan aiki; akasin haka, tsagi yana da zurfi. Lamarin dai akasin haka ne. Saboda haka, ya kamata a yi amfani da kayan da ke da zafi (irin su polyvinyl chloride) tare da zurfafa zurfafawa; don robobi tare da ƙarancin narkewar ɗanɗano da kwanciyar hankali mai ƙarfi (kamar polyamide), ya kamata a yi amfani da sukurori mara ƙarfi.

1. Rabewar dunƙule

Lokacin da kayan ke motsawa gaba tare da dunƙule, yana jure wa canje-canje a cikin zafin jiki, matsa lamba, danko, da dai sauransu. Wannan canjin ya bambanta a cikin cikakken tsayin dunƙule. Dangane da halaye masu canzawa na kayan, ana iya raba dunƙule zuwa ƙara (aika) sassan kayan abu da matsawa. Segment da homogenization kashi.

1. Jihohi uku na robobi da robobi

Filastik suna da nau'i biyu na thermosetting da thermoplastic. Bayan an gyare-gyaren robobi na thermosetting kuma an warke, ba za a iya dumama su da narkewa ba. Thermoplastic gyare-gyaren labarin za a iya sake yin zafi kuma a narke cikin wasu labaran.

Yayin da yanayin zafi ya canza, thermoplastic yana haifar da canjin yanayi uku na yanayin gilashi, babban yanayin roba da yanayin kwararar danko. Maimaita canje-canje tare da zafin jiki, jihohin uku suna haifar da canje-canje mai maimaitawa.

a. Daban-daban halaye na polymer narke a cikin uku-state:

Yanayin gilashi - filastik yana bayyana a matsayin m; Ƙarfin motsi na thermal ƙananan ne, ƙarfin intermolecular yana da girma, nakasar da aka fi amfani da ita ta hanyar lalacewar kusurwar haɗin gwiwa; bayan an cire ƙarfin waje, ana dawo da nakasar nan take, na nakasar gabaɗaya.

Matsayi mai mahimmanci - filastik abu ne mai kama da roba; nakasawa yana ba da gudummawa ta hanyar daidaitawa na macromolecular stretch wanda ya haifar da daidaitawar sashi, kuma ƙimar lalacewa yana da girma; bayan an cire ƙarfin waje, za a iya dawo da nakasar amma ta dogara da lokaci, wanda shine babban nakasawa.

Yanayin kwarara mai ɗanɗano - robobi suna bayyana azaman narke sosai; Ƙarfin zafi yana ƙara ƙarfafa motsin motsin ƙwayoyin sarkar; nakasar ba ta iya jurewa kuma tana cikin nakasar filastik

b. Sarrafa Filastik da Jiha uku:

Machinable a cikin gilashin filastik. Gyaran aiki a cikin babban yanayi na roba, kamar zanen waya, extrusion bututu, gyare-gyaren busa da thermoforming. A cikin yanayin kwararar danko, ana iya shafa shi, rotomolded da gyare-gyaren allura.

Lokacin da zafin jiki ya fi yanayin kwararar danko, filastik za ta lalace ta hanyar zafi, kuma lokacin da zafin jiki ya yi ƙasa da yanayin gilashin, filastik ɗin za a ƙwanƙwasa. Lokacin da zafin jiki na filastik ya fi yanayin kwararar danko ko ƙasa da yanayin gilashin, thermoplastic yana da'awar lalacewa da lalacewa sosai, don haka ya kamata a guji yankunan zafin jiki guda biyu yayin sarrafawa ko amfani da samfurin filastik.

Ƙofar da tagogi an yi shi da foda na PVC. Plastic extruder Gearbox ana amfani da ko'ina azaman bayanin taga da kofa, da kayan ado. Tare da fasaha na zamani da ingantaccen ƙira, yana da dukiya na babban ƙarfin fitarwa, tsawon rayuwa da filastik.

Filastik extruder Gearbox ne irin samar line aka tsara don extrusion na PVC filastik doos da windows profiles da giciye-section na USB bututu, Aluminum-roba hada profiles, da dai sauransu Yana da barga plastification, high fitarwa, low sheering karfi, tsawon rai sabis. da sauran fa'idodi. Ana iya amfani da bayanan martaba na PVC a cikin masana'antar gini da gida ko ofis.

Lubrication da sanyaya, dumama

Gears da bearings ana shafawa da wuraren tafkunan mai da fantsama. Bugu da kari ga fesa lubrication. ZLYJ jerin Akwatin kayan aiki mai wuyar gaske kuma sama bearings an kara zuwa ga man famfo lubrication tsarin for tilasta wurare dabam dabam lubrication.

Matsakaicin man mai mai matsakaicin matsakaicin matsakaicin gear mai N220 ko wani babban mai skating mai inganci mai ɗanko iri ɗaya.

Lokacin da yanayin zafi ya yi ƙasa da 0 ° C, ana ƙara bututun dumama wutar lantarki zuwa tafkin mai don dumama man mai.

Lokacin da yanayin yanayi ya fi 35 ° C, kamfaninmu yana yin lissafin ma'aunin zafi bisa ga ƙimar zafin da mai amfani ya bayar don sanin ko ƙara na'urar sanyaya.

ZLYJ jerin cylindrical bevel gearbox Samfurin Akwatin Gear:

Ƙayyadaddun bayanai sune: ZLYJ112, 133, 146, 173, 200, 225, 250, 280, 315, 330, 375, 420, 450; SJY224, 250, 280, 315; ZSYJ315, 375, 395, 420, 450, 560; 6E, 7E, 8E, 9E, 10E, 12E, 15E, JHM da sauran roba da roba masana'antu-takamaiman gearbox (za a iya musamman ga daban-daban wadanda ba misali manyan gearboxs).

Single dunƙule extruder Single dunƙule roba extruder for roba extruder inji

Tare da gaisuwa mafi kyau,

Cherry Zhang (Sashen Talla; Miss.)

NER GROUP CO., LIMITED

Yantai Bonway Manufacturer Co., Ltd.

Tel: + 86-535-6330966

Wayar hannu: + 86-18865558975

www.planetary-gearbox.com

https://twitter.com/gearboxmotor

https://www.facebook.com/sogears1993

Viber / Layi / Whatsapp / WeChat: 008618865558975

Imel:

Ara: No.5 Wanshoushan Road Yantai garin Lardin Shandong, China

Mafi kyawun sabis daga ƙwararrun mashigarmu zuwa akwatin sa ino mai shiga kai tsaye.

Our Service

Samun shiga

Yantai Bonway Manufacturer Co.ltd

Ano.160 Changjiang Road, Yantai, Shandong, China(264006)

T + 86 535 6330966

W + 86 185 63806647