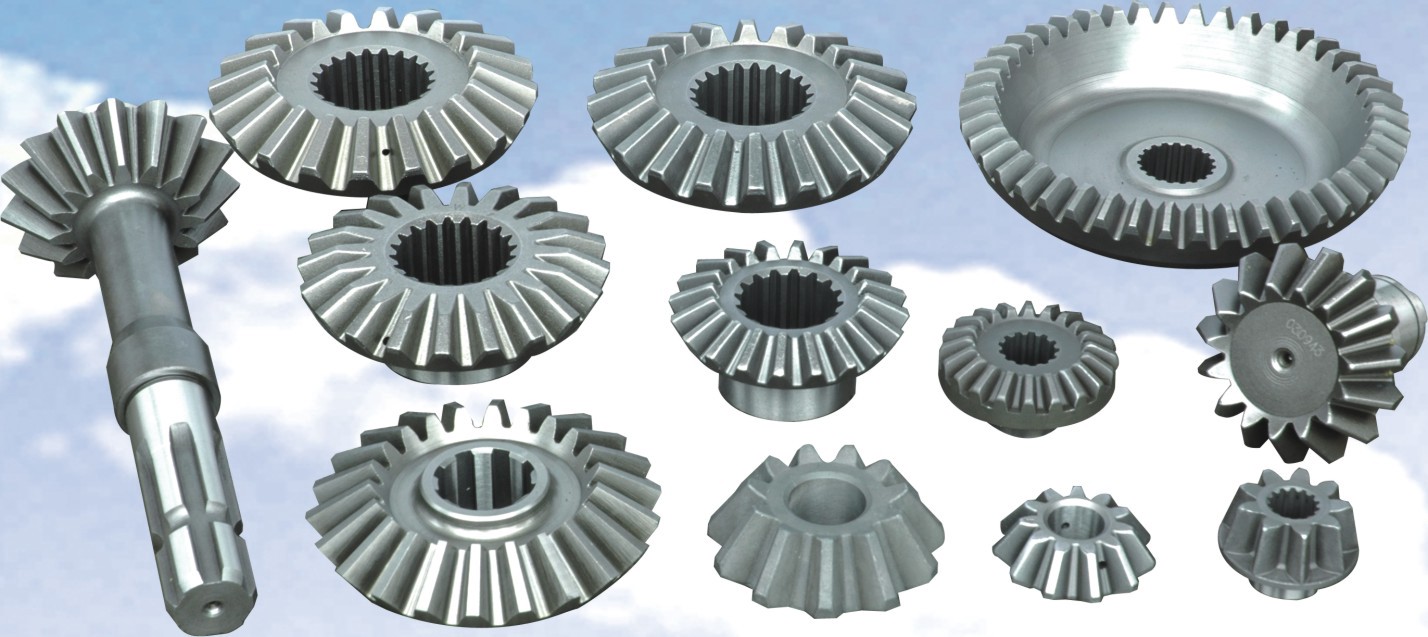

Ana amfani da gear ɗin da aka yi amfani da shi don isar da motsi da iko tsakanin ramukan da ke tsaka da juna. A cikin injuna gabaɗaya, kusurwar tsaka-tsaki tsakanin ramukan biyu na gears ɗin bevelled daidai yake da 90° (amma yana iya ƙila bai kai 90° ba). Hakazalika da gear silindari, bevelled gears suna da madaidaitan mazugi, mazugi na addendum, mazugi na tushen hakori da mazugi na tushe. Mazugi yana da babban ƙarshe da ƙarami, kuma da'irar da ta yi daidai da babban ƙarshen ana kiranta da'irar index (radius r), da'irar addum, da'irar tushen da da'irar tushe. Motsin gyaggyarawa guda biyu ya yi daidai da nau'i-nau'i na mazugi don mirgina zalla.

Samuwar bayanin martabar hakori:

Samuwar bayanin martabar haƙori na gears ɗin bevelled yayi kama da na gears cylindrical, sai dai ana amfani da mazugi na tushe maimakon silinda mai tushe. Samfuran saman S yana tangent zuwa janareta na mazugi na tushe. Lokacin da samar da saman S ke birgima tare da mazugi na tushe, duk wani madaidaiciyar layi OK akan farfajiyar samar da tuntuɓar janareta ON na mazugi na tushe zai samar da wani wuri mai lanƙwasa a sarari. Wannan mai lanƙwasa ita ce bayanin martabar haƙori mai lanƙwasa na madaidaicin gears. Halin kowane batu akan layin Ok shine involute (involute a vertex O shine aya). Kowane batu akan involute NK yana da daidaito daga mazugi O, don haka involute ɗin dole ne ya kasance a kan wani wuri mai siffar siffar siffar mazugi O kuma radius yayi kyau, wato NK involute ne mai siffar zobe.

ka'ida:

Hakora da wuraren haƙori na gears ɗin da aka ƙulla duk an haɗa su, wato, suna da faɗi a babban ƙarshen kuma kunkuntar a ƙaramin ƙarshen. Ko da yake an ɗaga kan madaidaicin zuwa kusurwar mazugi a lokacin aiki, babban ƙarshen farfajiyar waje na ƙwanƙwasa gear ɗin ya ɗan fi tsayi fiye da ƙaramin ƙarshen, kuma babban ƙarshen yana yanke zurfi fiye da ƙaramin ƙarshen lokacin niƙa, kuma nisa na tsagi hakori shima ya fi babban karshen girma. Ƙarshen ƙananan yana ɗan faɗi kaɗan, amma wannan bambanci ba zai iya cika bukatun ba. Wajibi ne don niƙa ƙarin a bangarorin biyu na babban ƙarshen. Lokacin da ake niƙa ƙwanƙwasa a kan injin niƙa, bayan an niƙa ramin haƙori na tsakiya a karon farko, an sami bayanan haƙorin babban ƙarshen, amma girman nisan ramin bai cika buƙatu ba. Don haka, kowane ramin haƙori gabaɗaya yana buƙatar niƙa sau uku don cimma manufar niƙa da yawa a ɓangarorin biyu na babban ramin haƙori, niƙa gefen gefen biyu na gears ɗin haƙori ana kiransa milling. Ka'idar milling diyya ita ce: a gefe guda, aikin aikin yana karkatar da shi; a daya hannun, worktable aka koma don gyara kananan ƙarshen tsagi hakori tare da milling abun yanka. Yin amfani da bambance-bambancen kashewa tsakanin babban ƙarshen da ƙaramin ƙarshen daidai gwargwado ga jagorar ciyarwa (mai juyawa) lokacin da aka karkatar da aikin aikin, ana ƙara ba da izinin niƙa a hankali daga ƙaramin ƙarshen zuwa babban ƙarshen, kuma babban ƙarshen ya fi niƙa nesa.

A halin yanzu, akwai hanyoyin niƙa da yawa a lokacin da ake niƙa gears, amma saboda rashin daidaituwar rabon farar da faɗin hakori (watau R/b), da kuma bambancin sigogi kamar kusurwar farar da adadin adadin. hakora, kowace hanya ba za a iya amfani da duk cones. sarrafa Gear, sabili da haka, za a iya zaɓar kawai bisa ga takamaiman yanayi kuma a gyara a yanke gwaji. Sau da yawa a yi amfani da haɗin jujjuyawa da kashewa don niƙa.

tsarin samar da gears:

1. Da farko, yi amfani da ƙa'idar hobbing don sanya kayan aikin injin da injin felu da na'urar shebur ta yi ta yin hobing akai-akai. Kayan aiki shine mai tsarawa tare da madaidaicin yankan gefuna guda biyu, wanda aka sanya akan mai riƙe kayan aiki, kuma yana maimaituwa tare da mai riƙe kayan aiki na motsi na layi.

2. An shigar da mariƙin kayan aiki akan shimfiɗar jariri don samar da kayan aikin shebur. Na'urar shebur da aka zayyana tana jujjuyawa daga sama zuwa kasa kuma daga kasa zuwa sama tana kewaya layin axis nata, kuma kayan aikin da aka sarrafa ana dora su a kan babban mashigin karamin akwatin, sannan a matsar da akwatin sub-gear don yin tip ɗin bevel. na kayan aikin da aka sarrafa da ƙirar shebur gear bevel tip Coincide, kuma sanya kusurwar tushen haƙori daidai da saman da tip ɗin kayan aiki ya wuce.

3. A lokacin yankan kaya, shimfiɗar jariri da na'urar da za a naɗa bi da bi suna yin ƙungiyoyin haɗin gwiwa a kusa da axis, wato, kamar dai ragargaza gears guda biyu, na'urar da za a naɗa za ta kasance a ƙarƙashin wannan shigarwa.

4. Layin axis da layin rotary na shimfiɗar jariri sun haɗu a wani wuri, wanda shine tsakiyar kayan aikin inji. Irin wannan motsi na juna yana ba mai tsara shirin tsara madaidaicin bayanin martabar haƙori.

Dangane da lamba da modules na workpiece, an ƙaddara don tsara kayan aiki tare da hanyar haƙori ɗaya ko hanyar haƙori biyu. Don samar da ƙananan guntu guda ɗaya, hanyar haƙori ɗaya gabaɗaya ana amfani da shi don tsara kayan aiki.

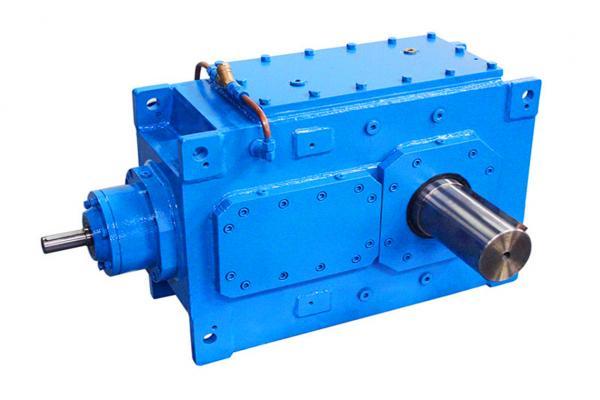

Karkaye bevelled gears da high watsa yadda ya dace, barga watsa rabo, babban baka zoba coefficient, high dauke iya aiki, barga watsa, m aiki, m tsarin, makamashi ceto da kuma kayan ceto, sarari ceto, sa juriya, tsawon rai da kuma low amo.

Fa'idodin na'urorin ƙwanƙwasa masu karkace (idan aka kwatanta da madaidaicin ginshiƙan bevelled):

1. Ƙara ma'auni na lamba, wato, ƙara yawan haɗin gwiwa, rage tasiri, daidaita watsawa, da rage amo.

2. Ƙaƙwalwar ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun kayan aiki sun karu sosai, kuma rayuwar sabis yana da tsawo.

3. Ana iya aiwatar da babban rabo na watsawa, kuma adadin ƙananan ƙafafun na iya zama kaɗan kamar 5 hakora.

4. Haƙori na haƙori na iya zama ƙasa don rage amo, inganta wurin hulɗar da inganta haɓakar haƙori. Madaidaicin niƙa na kayan aiki na iya kaiwa matakin 5.

An yi amfani da kayan kwalliyar karkace a ko'ina a cikin kayan bugawa, bambance-bambancen mota, da sluices. Hakanan za'a iya amfani da su a cikin locomotives, jiragen ruwa, masana'antar wutar lantarki, masana'antar karfe, binciken hanyar jirgin ƙasa, da dai sauransu. Idan aka kwatanta da kayan aikin ƙarfe, kayan aikin filastik suna da tattalin arziki, suna da tsayin daka mai jurewa, kuma suna aiki sosai.

Fasalolin kayan ƙwanƙwasa:

Dogon rayuwa, babban nauyin ɗaukar nauyi

Ƙarfin sinadarai da juriya na lalata

Amo da raguwar girgiza

Hasken nauyi da ƙarancin farashi

Sauƙi don siffa, mai kyau mai kyau

Hanyar gyara kaurin haƙori yayin da ake niƙa:

Bayan an cire niƙa a ɓangarorin biyu na haƙora 2 zuwa 3 tare da hanyar da ke sama, ya kamata a duba manyan da ƙananan ƙarshen haƙoran. Idan ainihin ƙimar da aka auna ba ta dace da ƙimar da aka yiwa alama akan zane ko ƙididdigewa ba, kuna buƙatar gyara adadin juyawa da kashewa. Ka'idar gyara ita ce:

1. Idan girman ƙananan ƙarshen daidai ne kuma akwai gefe don babban ƙarshen, adadin jujjuyawar (ko kusurwar jujjuyawar) da kashewa ya kamata a ƙara don ƙara bambanci ta yadda ƙaramin ƙarshen ya daina niƙa.

2. Idan girman babban ƙarshen daidai ne kuma kauri na haƙori na ƙaramin ƙarshen yana da gefe, adadin jujjuyawar (ko kusurwar jujjuyawar) ya kamata a rage don rage yawan kashewa. Karamin karshen kuma ana nika shi, babban karshen kuma ba a nika shi.

3. Idan duka babban ƙarshen da ƙarami suna da tazara, kuma tazarar sun yi daidai, kawai buƙatu ne kawai a rage abin da aka kashe ta yadda duka babban ƙarshen da ƙaramin ƙarshen su shuɗe.

4. Idan girman ƙaramin ƙarshen ya yi daidai kuma girman babban ƙarshen ya yi ƙanƙara, sai a rage adadin jujjuyawar (ko kusurwar jujjuyawar), kuma a rage kashe kuɗin daidai yadda ƙaramin ƙarshen ya daina. niƙa kashe, kuma babban karshen an yanke kasa da na asali wasu.

5. Idan girman babban ƙarshen ya yi daidai kuma girman ƙananan ƙananan ya yi ƙanƙara, sai a ƙara yawan jujjuyawa (ko karkatarwar kusurwa), kuma a ƙara diyya kaɗan, ta yadda ƙaramin ƙarshen ya kasance. niƙa ƙasa da na asali. Idan kaurin haƙori na ƙaramin ƙarshen ya yi ƙanƙanta sosai lokacin niƙa tsakiyar tsagi, kuna buƙatar maye gurbin abin yankan niƙa ko yin abin yanka na musamman don sarrafawa.

Gear yana nufin kayan aikin inji tare da giya akan bakin da ke ci gaba da harbawa don watsa motsi da iko. Aikace-aikacen giya a cikin watsawa ya bayyana da wuri. A ƙarshen karni na 19, ƙa'idar hanyar yankan kayan aiki da kuma kayan aikin masarufi na musamman da kayan aikin da suka yi amfani da wannan ka'idar don yanke kayan sun bayyana ɗayan bayan ɗaya. Tare da ci gaban samarwa, an mai da hankali ga laushin kayan aiki.

Rarraba tsarin:

Gabaɗaya, akwai haƙoran gear, raƙuman haƙori, fuskokin ƙarewa, fuskoki na yau da kullun, da'ira, da'irar tushen hakori, da'irorin tushe, da da'irori.

Hakoran hakora

Ana magana da shi azaman haƙori, shi ne kowane ɓangaren juzu'i na kayan aikin da ake amfani da shi don haɗawa. Gabaɗaya waɗannan sassan sassaƙaƙƙun ɓangarorin an shirya su cikin tsarin radial. Haƙoran da ke kan kayan haɗin gwal suna hulɗa da juna, ta yadda kayan za su iya ci gaba da yin raga da gudu.

Cogging

Yana da sarari tsakanin hakoran gear biyu maƙwabta akan kayan; fuskar karshen tana kan gear silinda ko tsutsar silinda, kuma jirgin saman daidai gwargwado ga axis na kaya ko tsutsa.

Karshen fuska

Shi ne jirgin a karshen biyu na kaya.

Dharma

Yana nufin jirgin sama daidai da layin hakori na kayan aiki.

Addendum da'irar

Yana nufin da'irar inda titin hakori yake.

Da'irar tushen hakori

Yana nufin da'irar inda kasan tsagi yake.

Da'irar tushe

Layin da ke samar da involute shine da'irar mirgina zalla.

da'irar fihirisa

Da'irar tunani ce don ƙididdige ma'auni na geometric na kayan aiki a ƙarshen fuska.

rarrabuwa:

Za'a iya rarraba giya bisa ga yanayin haƙori, surar gear, surar layin haƙori, saman da haƙoran haƙar take, da kuma hanyar masana'antu.

Bayanin haƙori na kaya ya haɗa da ƙwanƙolin bayanin haƙori, kusurwar matsin lamba, tsayin haƙori da kuma sauyawa. Rarraba kayan aiki sun fi sauƙin kerawa, don haka a cikin giya na zamani, lissafin abubuwan da ba a yarda da su ba yana da cikakken rinjaye, yayin da ba a amfani da giya na cycloid da arc.

Dangane da kusurwar matsin lamba, giya tare da ƙananan kusurwa na da ƙaramar ƙarfin ɗaukar nauyi; giya tare da manyan matattarar kusurwa suna da ƙarfin ɗaukar nauyi, amma nauyin da ke kan ɗaukar yana ƙaruwa a ƙarƙashin ƙirar juzu'i iri ɗaya, don haka kawai ana amfani dashi a cikin lamura na musamman. An daidaita tsayin haƙori na gear, kuma ana karɓar daidaitaccen haƙori gabaɗaya. Akwai fa'idodi da yawa na giyar sauyawa, waɗanda aka yi amfani da su a cikin kayan aikin injina daban-daban.

Bugu da ƙari, ana iya raba gears zuwa gears na cylindrical, bevelled gears, gears marasa madauwari, racks, da gear tsutsotsi gwargwadon siffarsu; bisa ga siffar layin haƙori, ana iya raba su zuwa ginshiƙan spur, gears helical, gears herringbone, da gears masu lankwasa; bisa ga gear hakora An raba saman zuwa na waje gears da na ciki gears; bisa ga hanyar masana'anta, ana iya raba shi zuwa simintin gyare-gyare, yankan ginshiƙai, naɗaɗɗen ginshiƙan, da na'urorin sintepon.

Kayan masana'antu da aikin kula da zafin jiki na gear suna da tasiri mai yawa akan ƙarfin ɗaukar kaya da girma da nauyin kaya. Kafin shekarun 1950, galibi ana amfani da karafan carbon ne don giya, ana amfani da ƙarfe mai ƙarfe a cikin 1960s, kuma an yi amfani da ƙarfe mai ƙararraki a cikin 1970s. Dangane da taurin, za a iya rarraba farfajiyar haƙori zuwa gida biyu: saman haƙori mai laushi da farfajiyar haƙori mai tauri.

Gears tare da saman haƙori mai laushi suna da ƙananan ƙarfin ɗaukar nauyi, amma sun fi sauƙin ƙira kuma suna da kyakkyawan aiki. Ana amfani da su galibi a cikin injunan gabaɗaya ba tare da ƙaƙƙarfan ƙuntatawa akan girman watsawa da nauyi ba, da samar da ƙaramin ƙara. Domin karamar dabarar tana da nauyi mai nauyi a tsakanin injinan da suka dace, domin a sa rayuwar aiki na manya da kanana su zama daidai, taurin hakorin karamar dabarar gaba daya ya fi na babbar dabaran.

Gyaran da suka taurara suna da karfin daukar nauyi. Bayan an yanka giya, sa'annan a huce, farfajiyar ƙasa ko ƙwanƙwasawa da ƙwanƙwasawa don ƙara taurin. Amma a cikin maganin zafin rana, babu makawa gear zai sami nakasa, don haka bayan an gama maganin zafi, nika, nika ko yankan laka dole a aiwatar dashi don kawar da kuskuren da nakasa ta haifar da kuma inganta daidaito na kayan.

material

Karfe da aka saba amfani da su don yin gears ana kashe su da ƙarfe mai zafi, ƙarfe mai kashewa, carburized da quenched karfe da nitrided karfe. Ƙarfin simintin ƙarfe yana ɗan ƙasa kaɗan fiye da na jabun ƙarfe, kuma galibi ana amfani da shi don manyan gears; baƙin ƙarfe simintin launin toka yana da ƙayyadaddun kayan inji kuma ana iya amfani dashi a cikin watsa kayan buɗaɗɗen kaya; baƙin ƙarfe ductile zai iya maye gurbin karfe don yin gears; An fi amfani da gear robobi A wuraren da ake buƙatar nauyi mai sauƙi da ƙaramar amo, gear ɗin da aka haɗa gabaɗaya suna amfani da injin ƙarfe tare da kyakkyawan yanayin zafi.

A nan gaba, gears suna tasowa a cikin jagorancin nauyi mai nauyi, babban sauri, babban madaidaici da ingantaccen aiki, kuma suna ƙoƙari su zama ƙananan girman, haske a nauyi, tsawon rayuwa da tattalin arziki da abin dogara.

Haɓaka ka'idar kayan aiki da fasahar kere kere za ta ƙara yin nazari kan tsarin lalata haƙoran gear, wanda shine tushen kafa ingantacciyar hanyar ƙididdige ƙarfin ƙarfi, da tushen ka'idar don haɓaka ƙarfin ɗaukar kaya da haɓaka rayuwar kayan aiki; ci gaban yana wakilta ta hanyar bayanan haƙori na baka Sabon bayanin haƙori; bincika sabbin kayan aiki da sabbin fasaha don kera kayan aiki; bincika nakasar kayan aiki na roba, kurakuran masana'anta da shigarwa, da rarraba filayen zafin jiki, da kuma gyara haƙoran haƙora don haɓaka sassaucin aikin kayan aiki. A lokacin da ƙara lamba yankin na gear hakora, don inganta hali iya aiki na kaya.

Gwagwarmaya, ka'idar lubrication da fasahar lubrication sune ainihin aikin bincike na kayan aiki. Bincike kan ka'idar lubrication na elastohydrodynamic, haɓaka yin amfani da mai mai mai da roba kuma daidai da ƙara matsananciyar ƙari ga mai, wanda ba zai iya haɓaka ƙarfin ɗaukar haƙoran kawai ba, amma kuma yana iya haɓaka haɓakar watsawa.

Bambance-bambance tare da kayan kwalliyar hypoid:

Gishiri mai karkace da kayan kwalliyar kayan kwalliya sune manyan hanyoyin watsawa da ake amfani da su a cikin masu rage motoci na ƙarshe. Menene banbancin su?

Babban gatari da tuƙi na gear suna haɗuwa a wuri guda, kuma kusurwar tsaka-tsakin na iya zama mai sabani, amma a yawancin tuƙin tuƙin mota, babban nau'ikan kayan rage kayan aiki suna ɗaukar tsari na tsaye na 90°. Saboda haɗuwa da ƙarshen fuskokin haƙoran gear, aƙalla nau'i-nau'i biyu ko fiye na ragar haƙoran gear a lokaci guda. Don haka, ƙwanƙolin karkace na iya ɗaukar kaya mai girma. Bugu da kari, gear hakora ba su ragargaza a lokaci guda a kan cikakken tsawon hakori, amma a hankali ragargaje daya karshen yana ci gaba da juya zuwa daya karshen, don haka da cewa yana aiki smoothly, kuma ko da a high gudun, amo da vibration suna sosai. karami.

Gatura na injinan tuƙi ba sa haɗuwa amma suna haɗuwa a sararin samaniya, kuma kusurwar sararin samaniya tana ɗaukar kusurwa 90° daban-daban a tsaye na jirgin sama. Shagon kayan tuƙi yana da koma baya ko ƙasa dangane da tuƙi mai tuƙi (ana magana da babba ko ƙarami daidai da haka). Lokacin da biya diyya ya yi girma zuwa wani iyaka, shingen gear guda ɗaya na iya wucewa ta ɗayan kayan aikin. Ta wannan hanyar, ana iya shirya ƙaƙƙarfan bearings a ɓangarorin biyu na kowane kayan aiki, wanda ke da fa'ida don haɓaka ƙaƙƙarfan tallafi da tabbatar da daidaitattun haƙoran gear, don haka haɓaka rayuwar kayan aiki. Ya dace da ta-nau'in tuƙi axles.

Ba kamar karkatattun gears ɗin ba, inda manyan gears da masu tuƙi suke da kusurwar helix iri ɗaya saboda gatura na gear biyu suna haɗuwa, madaidaicin axis na nau'in kayan aikin hypoid yana sanya kusurwar helix na kayan tuƙi girma fiye da kusurwar helix na abin tuƙi. kayan aiki. Saboda haka, kodayake al'ada modulus na hypid ya jefa gears biyu daidai yake, yanayin fuska mai laushi ba daidai yake ba ya fi na kayan kwalliya). Wannan yana sa kayan tuƙi na watsa kayan beveled gears mai gefe-biyu suna da diamita mafi girma kuma mafi ƙarfi da ƙarfi fiye da kayan tuƙi na daidaitaccen karkace beveled gears. Bugu da ƙari, saboda babban diamita da kusurwar helix na kayan tuki na watsawa na hypoid bevelled gears, damuwa na lamba a kan haƙori yana raguwa kuma yana ƙara yawan rayuwar sabis.

Duk da haka, lokacin da watsawa ya yi ƙanƙanta, kayan tuƙi na watsa gear-gear-biyu-biyu ya yi girma da yawa idan aka kwatanta da na'urar tuƙi ta karkace. A wannan lokacin, yana da ma'ana mafi dacewa don zaɓar kayan aikin karkace.

Gishiri mai karkace, wato karkace gears, galibi ana amfani da su don motsi da watsa wutar lantarki tsakanin rafukan da ke tsaka da juna. Ana rarraba hakoran kayan aikin da aka yi a saman mazugi, kuma bayanan haƙori a hankali yana raguwa daga babban ƙarshen zuwa ƙaramin ƙarshen.

Gabatarwa:

Siffar haƙori na karkace gears mai siffar baka ne, kuma gabaɗaya suna da siffar mazugi, kamar sifar laima, don haka sunan karkace bevelled gears.

Karkatu bevelled gears wani yanki ne na watsawa wanda za'a iya watsa shi cikin sauƙi kuma tare da ƙaramar amo bisa ga ingantaccen rabon watsawa. Yana da sunaye daban-daban a yankuna daban-daban. Haka kuma ana kiranta da karkace, kayan kwalliyar kwalliyar kwalliyar kwalliyar kwalliyar kwalliyar kwalliyar kwalliyar kwalliyar kwalliyar kwalliyar kwalliyar kwalliyar kwalliyar kwalliyar kwalliyar kwalliyar kwalliyar kwalliyar kwalliyar kwalliyar kwalliya da sauransu.

Features:

Karkaye bevelled gears da high watsa yadda ya dace, barga watsa rabo, babban baka zoba coefficient, high ɗaukar iya aiki, barga da kuma santsi watsa, m aiki, m tsarin, makamashi ceto da kuma kayan ceto, sarari ceto, sa juriya, tsawon rai da kuma low amo.

Daga cikin watsawa daban-daban na inji, ingancin watsawar na'urori masu karkatarwa shine mafi girma, wanda ke da fa'idodin tattalin arziƙi ga nau'ikan watsawa daban-daban, musamman watsawa mai ƙarfi. Biyu watsawa da ake buƙata don watsa juzu'i iri ɗaya shine mafi ƙarancin ceton sarari. Wurin da ake buƙata don watsa sarkar ƙarami ne; da watsa rabo na karkace bevelled gears ne na dindindin barga, kuma barga watsa rabo sau da yawa shi ne ainihin abin da ake bukata don watsa aiki a watsa na daban-daban inji kayan aiki; karkace bevelled gears aiki amintacce kuma suna da tsawon rai.

aikace-aikace:

Spiral bevelled gears ana amfani da ko'ina a cikin gida da kuma waje oilfield petrochemical injuna, daban-daban inji kayan aikin, daban-daban machining kayan aiki, injiniya inji, karfe kayan aiki, karfe mirgina inji, ma'adinai inji, kwal ma'adinai inji, yadi kayan, shipbuilding inji, shipbuilding masana'antu, Aerospace, forklift , Elevators, Ragewa, jiragen sama masana'antu da yawa sauran masana'antu. Karfe bevelled gears ana amfani da a iri-iri na inji kayan aiki, yana nuna kyakkyawan aiki, kuma sun shahara a tsakanin masana'antun sararin samaniya, dakunan jiragen ruwa, injiniyoyin injiniyoyi, tsire-tsire na kayan aikin ƙarfe, tsire-tsire masu jujjuya kayan aikin ƙarfe, tsire-tsire masu jujjuya ƙarfe, masana'antar mirgina ƙarfe, Metallurgical inji, ma'adinai inji, kwal hakar inji shuka, mai filin petrochemical inji shuka, Yadi inji shuka, inji kayan aiki shuka, kayan aiki kamfanin, elevator kamfanin, jirgin sama masana'antu shuka, reducer shuka, kwal ma'adinai inji shuka, haske masana'antu inji shuka, haske masana'antu inji shuka, karfe mirgina niƙa , Karfe mirgina kayan aiki factory, karfe kayan aiki factory da sauran abokan ciniki.

Da fatan za a iya samun damar tuntuɓarmu kuma ga masu biye damu. Za mu amsa muku da wuri-wuri!

Mobile:+ 86-18563806647

Whatsapp / Wechat: 8618563806647

Imel:

Yantai Bonway Manufacturer Co.ltd

Ano.160 Changjiang Road, Yantai, Shandong, China(264006)

T + 86 535 6330966

W + 86 185 63806647